Gallery

The Craft Behind Clean Injectors

At Fuel Injector Man, Inc., every service we perform is backed by technical precision and visual proof. This gallery highlights the detailed, hands-on process that transforms clogged, uneven injectors into clean, balanced components ready for reliable performance.

Our images document the full journey—from the moment injectors arrive to final flow verification—showing why professional ultrasonic cleaning outperforms quick chemical solutions or in-tank additives. Whether you run a Yamaha outboard, Mercury OptiMax, Evinrude E-TEC, or automotive performance setup, our attention to detail remains the same.

The Ultrasonic Cleaning Process

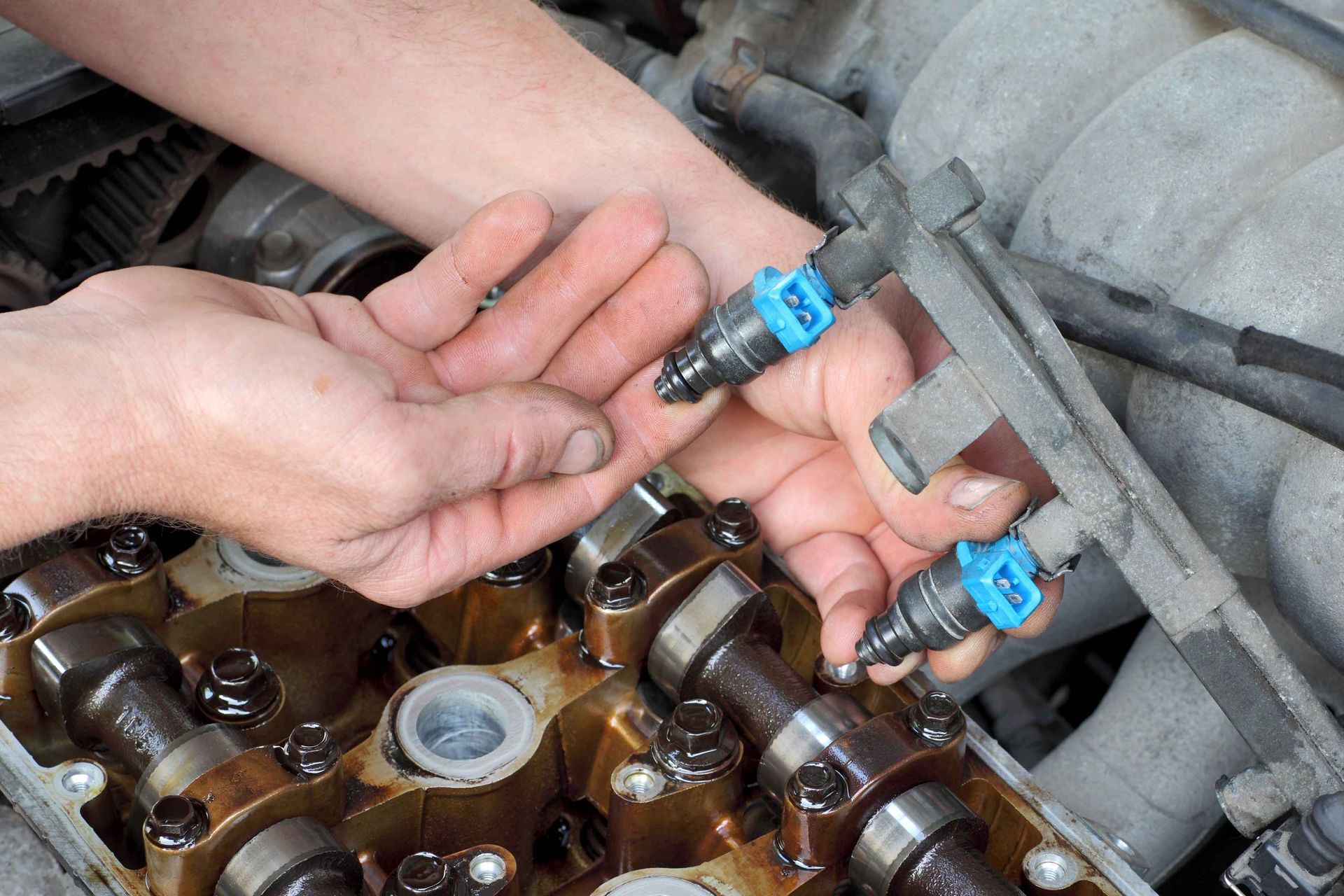

Before & After: Restoring Balance

Photos in this section would display injectors before cleaning—dark, carbon-coated, and restricted—alongside after-service shots showing polished metal surfaces, clean pintle tips, and replaced O-rings.

Each image demonstrates what microscopic debris and fuel varnish can do to spray quality over time, and how ultrasonic cleaning completely restores uniformity.

Suggested Captions:

- “Top-feed Yamaha injectors before and after ultrasonic cleaning.”

- “Mercury OptiMax air and fuel injectors following full reverse-flush and seal replacement.”

- “Visible improvement in spray pattern and atomization after flow restoration.”

By showing visual comparisons, customers immediately understand the value of professional injector service.

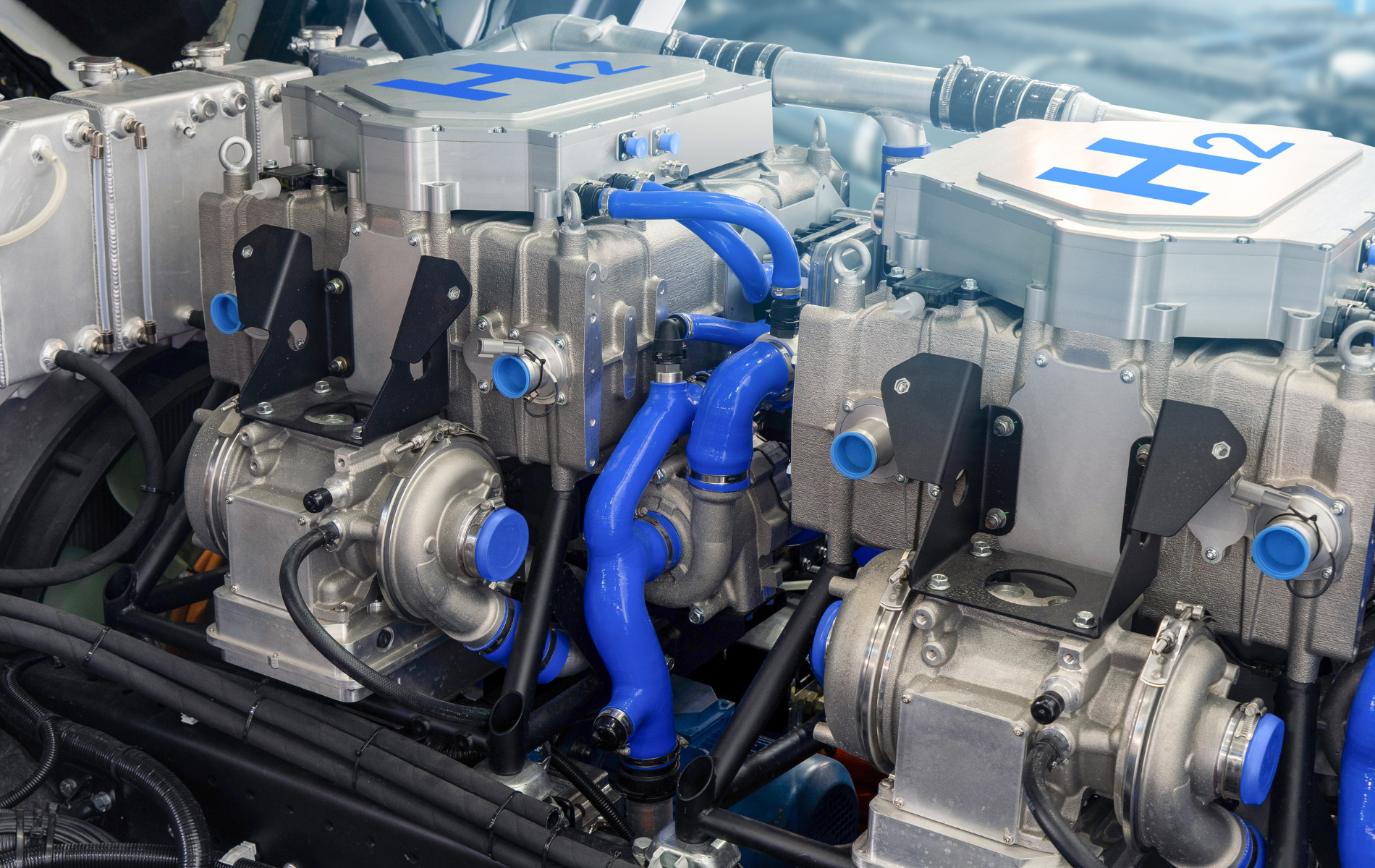

Marine Injector Service in Detail

Outboard Performance, Verified

These images focus on the marine environment—injectors from Yamaha, Honda, Suzuki, and Mercury engines tested under calibrated conditions. You might include photos of:

- Injectors arranged on the flow bench during testing.

- The measurement beakers showing equalized flow volumes.

- Spray pattern verification in progress, demonstrating atomization consistency.

Suggested Captions:

- “Six-cylinder Yamaha HPDI injectors balanced to less than 1% variance.”

- “Flow testing Mercury OptiMax injectors to verify even delivery across all cylinders.”

- “Every marine set receives a documented flow report confirming post-clean balance.”

These visuals reinforce your expertise in the marine market and your ability to handle complex systems like HPDI, OptiMax, and E-TEC with accuracy.

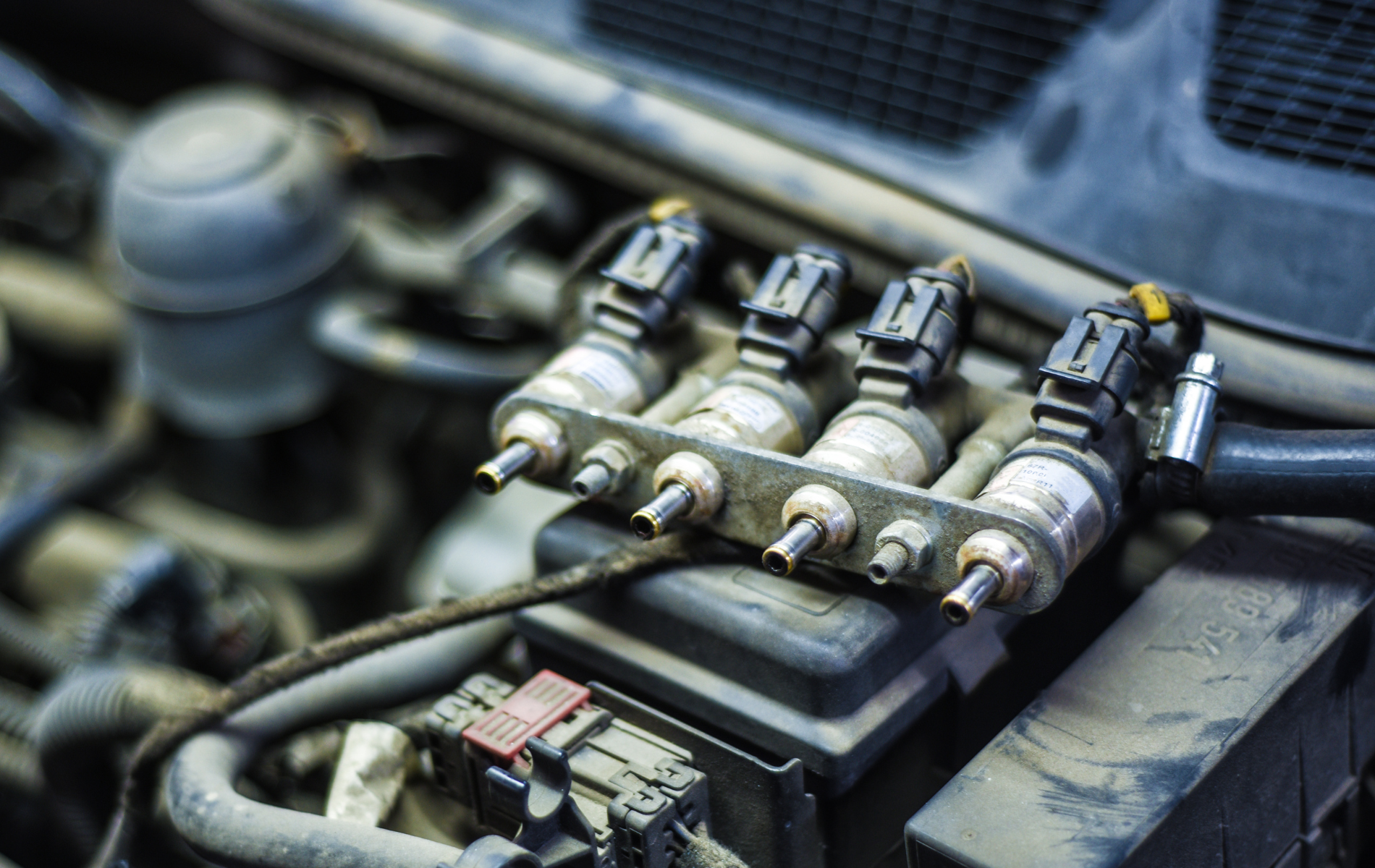

Automotive Injector Cleaning & Flow Testing

Restoring Road Performance

Automotive injectors benefit from the same precision marine customers rely on. This gallery section can include:

- Side-by-side before/after photos of typical port-fuel automotive injectors.

- Close-ups of internal filter baskets removed during cleaning.

- Flow-bench testing showing improved spray patterns and uniform stream angles.

Suggested Captions:

- “Automotive port-fuel injectors after ultrasonic cleaning and flow verification.”

- “Restored spray pattern ensuring smooth idle and improved fuel economy.”

- “Every injector tested under multiple duty cycles for accuracy.”

These images help car owners visualize how internal buildup affects performance and how your cleaning process resolves it completely.

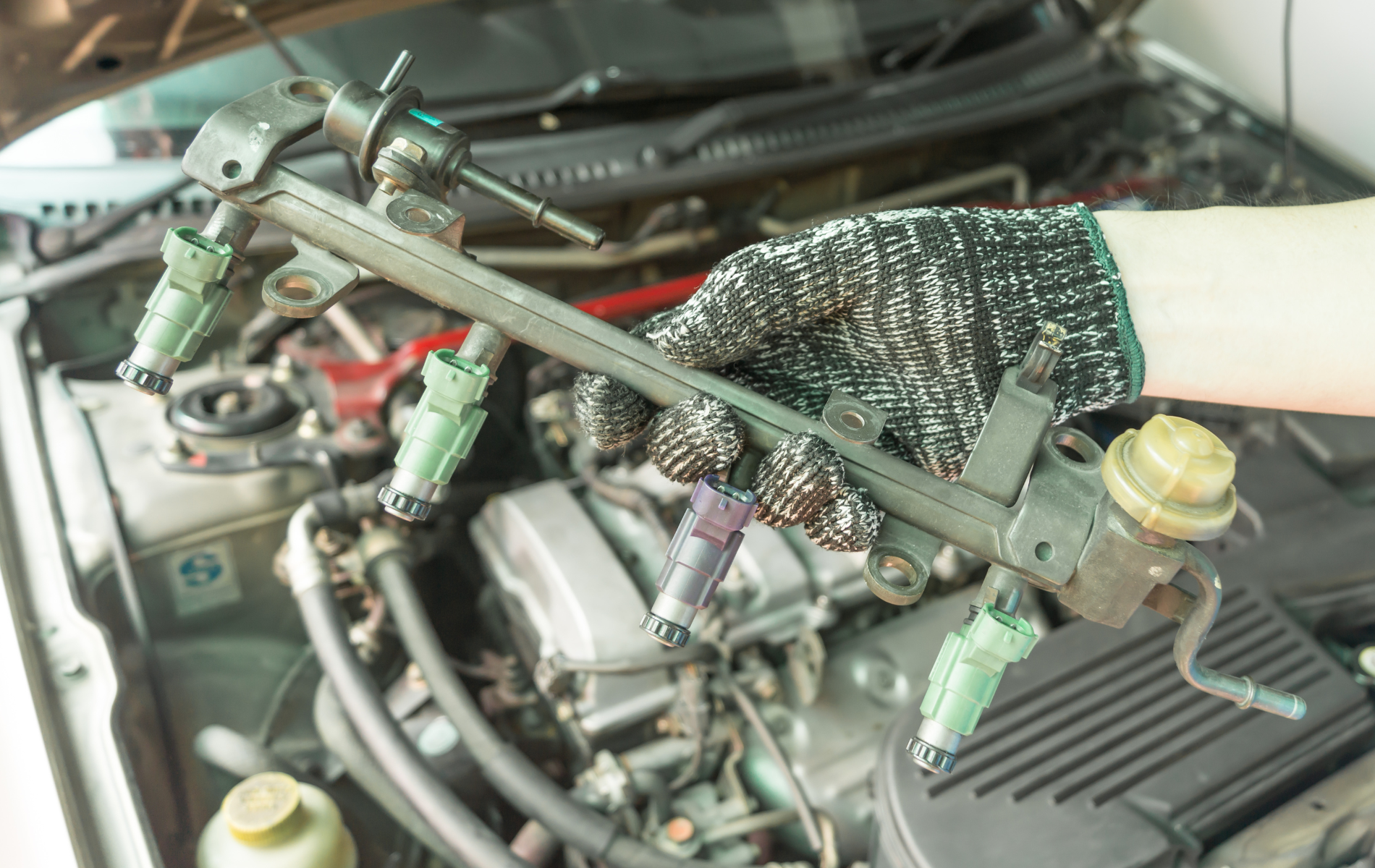

Side-Feed & OptiMax Injector Service

Specialized Equipment for Complex Designs

Side-feed injectors require unique fixturing and cleaning direction. This gallery section showcases the tools and precision required to handle these systems correctly.

Suggested Captions:

- “Side-feed injector cleaning using reverse-flow ultrasonic agitation.”

- “Mercury OptiMax fuel and air injectors during multi-point flow testing.”

- “Before/after comparison of side-feed injectors showing clear atomization improvements.”

Displaying specialized equipment emphasizes your capability and investment in professional-grade tools that ensure repeatable accuracy.

Evinrude E-TEC Injector Calibration & Cleaning

Set-Based Balance and Testing

Evinrude E-TEC injectors are matched electronically, so servicing them correctly requires testing entire sets together. Showcase:

- Complete injector sets labeled for cylinder order.

- Flow test results with near-identical readings after cleaning.

- The detailed printed reports that accompany every E-TEC job.

Suggested Captions:

- “E-TEC injector set cleaned, flow balanced, and resistance verified.”

- “Documented test results confirm matched calibration across all cylinders.”

- “Each injector cleaned ultrasonically and verified under E-TEC-specific procedures.”

These visuals give customers confidence that your E-TEC service maintains manufacturer-level precision.

Facility & Equipment

Professional Tools, Local Expertise

Showcasing your Naples facility adds credibility and personality to your business. Include photos of:

- The ultrasonic cleaning station in operation.

- The calibrated flow bench during multi-injector testing.

- Organized injector racks awaiting shipment or pickup.

Suggested Captions:

- “Professional ultrasonic cleaning equipment dedicated to marine and automotive injectors.”

- “Flow bench calibrated for accurate, repeatable results.”

- “All injectors labeled, tested, and documented before leaving our Naples facility.”

Including these behind-the-scenes details helps customers appreciate the professionalism and care that go into every order.

Why Our Gallery Matters

Your gallery isn’t just visual proof—it’s evidence of transparency and craftsmanship. Seeing real injectors, real tools, and real test data communicates credibility that words alone can’t match. Each image reinforces your process: methodical, data-driven, and backed by years of technical experience.

Customers who view this gallery gain confidence that their equipment will receive genuine, precision-grade service from a company that values results and integrity over marketing claims.

Contact Fuel Injector Man, Inc.

Ready to restore your injectors to factory-level performance? Contact Fuel Injector Man, Inc. today.